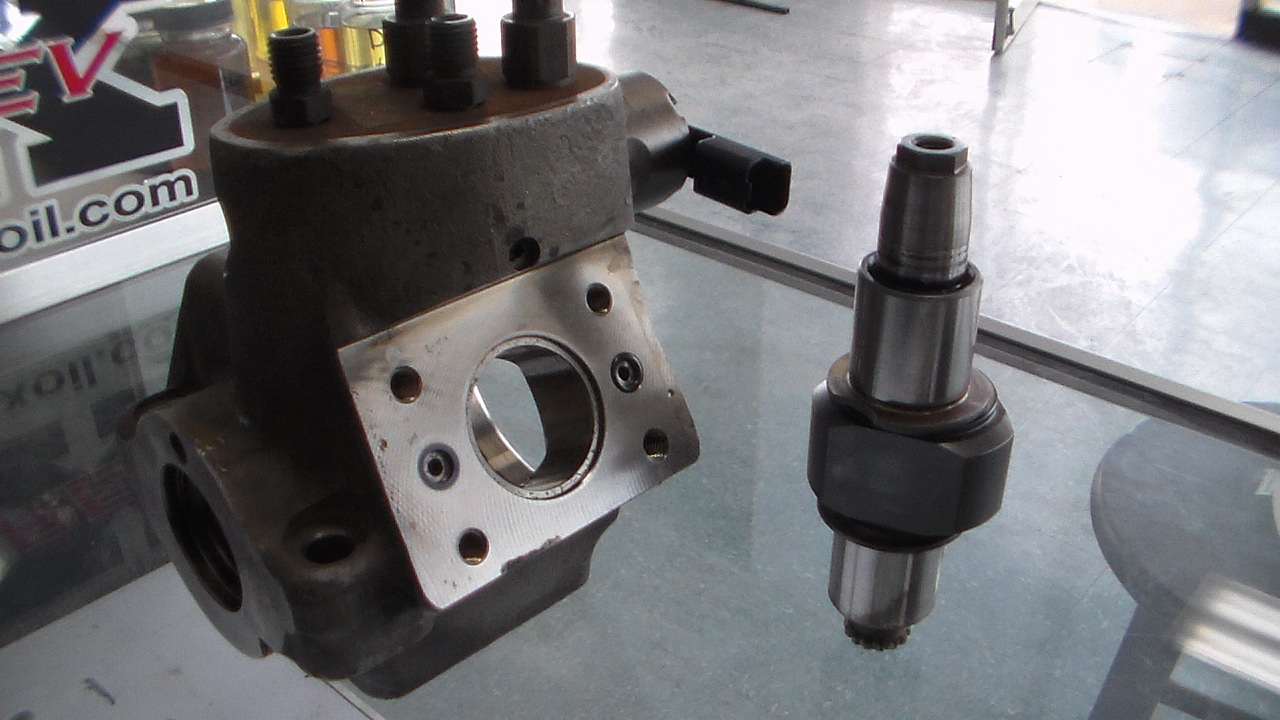

Watch the next installment of “whats Inside” and see the complexities of a 2008 Ford 6.4 Powerstroke injection pump.

Whats Inside? 2013 Duramax Injection Pump.

This will be the First of many “Whats Inside” videos and hopefully answer some of our curiosities.

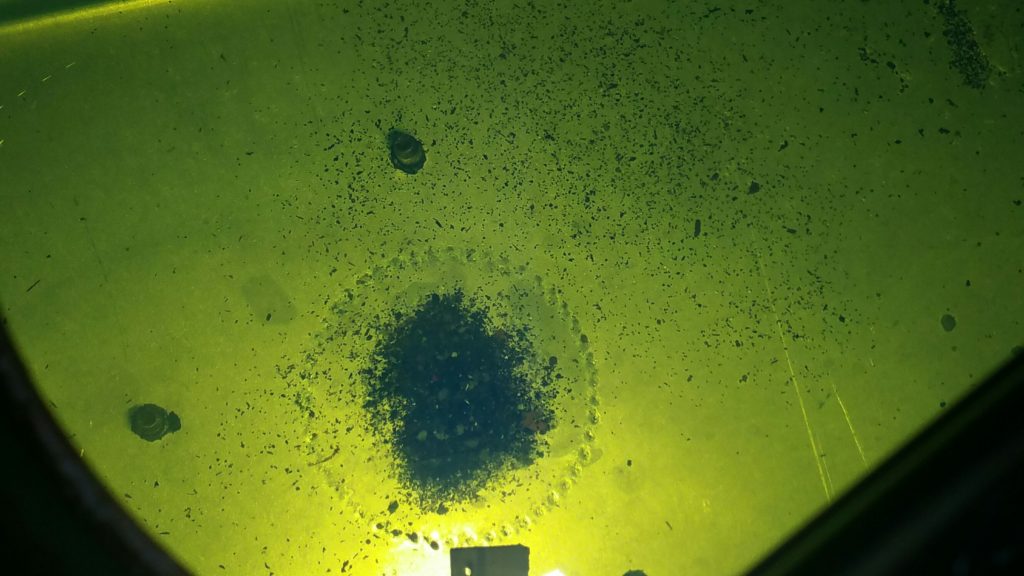

Fuel Tank Rust, Cause and Prevention.

Have you ever looked inside your steel fuel tanks? You probably don’t want to.

Many models of pickup trucks have steel fuel tanks that are not internally lined with anti corrosion material. This means nothing if the truck is constantly being driven, but if it gets parked for any more than a month moisture will condense on the inside of the tanks and corrode. The rust becomes loose and falls to the bottom when filling with fuel. The best way to prevent this from occurring is to fill your fuel tanks to the brim before parking the truck for extended periods of time. A full tank of fuel will ensure there wont be any air gap from the fuel level line to the top of the tank. This little piece of advice will save your tanks, injectors, pumps, fuel filters and wallet.

This happens so often we always advise removing and inspecting fuel tanks when debris is found in the fuel filters or a high or low pressure fuel pump goes down. There cant be anything worse than repairing a problem and immediately contaminating new expensive fuel system components.

Have you experienced this concern before?

Google in Your Tool Box

Most modern technicians will use many different tools and techniques to diagnose and repair various symptoms on a daily basis. Since most repair facilities take in more than one type of vehicle, it is important to be flexible. One tool stands out to be the most flexible, the internet.

Using the internet for advice can at times be fickle. Not all of the information you find is applicable! Forums and threads can be misleading.

Certain things can be quick and easy to find like DTCs, fluid capacities, cylinder identification, component location, part numbers, prices, diagrams, and fuse locations.

How useful is the internet to your daily routine?

IS Your Used Truck Tuned? NO! How Can You Be Sure?

Joe decides one day to trade in his 2005 Dodge Ram Cummins for a sweet new ride. Joe enjoyed the power and performance gains his tuner gave him for many years. The hardware Joe had put away to tune his truck was lost in his last divorce.

Lets take a ride to the imaginary used car lot for a bit. John the salesman takes the truck in on trade. The dash has no warning lights and the truck runs very well, should have no problem selling it.

Now you are you, and you find a truck that fits your needs perfectly. It has a fair price and you buy the truck.

Some time after, an engine light appears and generates codes that no one can seem to decipher. Any knowledgeable shop would probably see the weird malfunction and recommend a replacement PCM. This will fix the problem when the new PCM has been programmed with stock software. No one will know why it’s fixed, just that it is.

You pick the truck up and feel the truck isn’t right, its now under powered and gets poor fuel mileage. An automatic response to a new symptom occurring after an official repair is to blame the shop for doing something wrong. A return trip will prove nothing out of the ordinary exists and are sent back on your way.

This mysterious dragon syndrome occurs often, and the correct response is to tune over the corrupt tune file, or re-flash the PCM to stock and then tune over the stock file.

The Power Of Insight and Inspection During Diagnosis

It happens often and when you least expect it. You are driving down the road (minding your own business) and your engine begins to shudder for what seems like no reason at all, and then corrects its self. The symptom will be fleeting and pass quickly, but will inevitably return. The PCM (powertrain control module) is not likely to have generated a DTC (diagnostic trouble code) to help point a you in the direction of the failed component, so you start with the fuel filter. Right? Well chasing wiring concerns is no easy task. The symptoms may mimic that of a bad injector, poor fuel volume or quality, or even the turbo charger its self. With a little luck the problem will persist long enough to catch it in the act.

In this case specifically the technician used an advanced scan tool to perform an injector “Buzz Test”. Cylinder #3 did not buzz like all of his brothers, which prompted the inspection of the injector wiring harness to cylinder #3. Not long after pulling back the corrugated protective sheathing a single circuit was found rubbing on the valve cover causing a short to ground. In effect electrifying the block and not the injector. This circuit is responsible for sending a 48v charge to the injector from the FICM (fuel injector control module) and used to actuate the high voltage solenoid releasing a pocket of high pressure fuel into he combustion chamber. The technician repaired the circuit and protected it from further damage by insulating it with more tubing and electrical tape. Took the vehicle on a test drive, and sent this one on its way with little expense to the customer.

With out this insight an individual may have replaced an injector confidently being a know problematic component. It is of the utmost importance to eliminate a circuit failure before any hardware is replaced. A small investment in time will save untold amounts of money in parts or repair. Parts stores don’t like to return “test” parts.