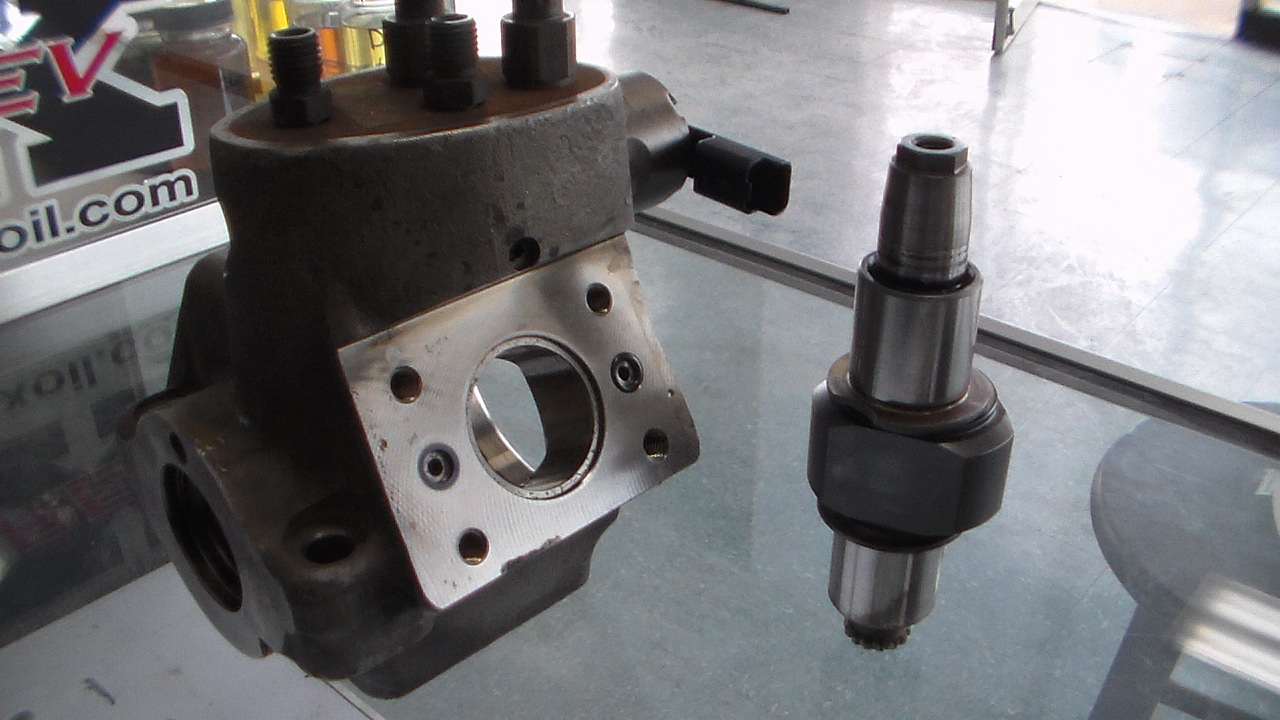

Watch the next installment of “whats Inside” and see the complexities of a 2008 Ford 6.4 Powerstroke injection pump.

Practicle Jokes, 10 Safe Ways To Stir Things Up + 10 Unsafe Ways.

Every job has its difficulties, and auto/diesel repair is riddled with them. One way to offset this dark element of employment is to commence practical joking. Many technicians prefer not to disturb their cohorts while working, but there are moments of the day that aren’t filled with diagnostic or repairs. This time can be used constructively, or not. Here are ten things I have seen in a shop environment that would be considered the most common and relatively SAFE ways to stir things up.

- Grease under tool box or car door handles.

- Reorganization of tools in others tool boxes.

- Throw a charged capacitor to an unsuspecting operator.

- Actuating a car horn at inopportune moments.

- Blowing up a coolant or oil jug under someones tool box using shop air.

- Closing a hood on some one in a compromising position.

- Pulling strategic fuses in a vehicle to exhibit acute symptoms.

- Covertly drop a tailgate on a truck backing up.

- Long zip ties attached to driveshaft.

- Use a rack to lift a large tool box high off the ground.

These next ones should NOT be performed by anyone, but have been documented as “Impractical Jokes”

- Brake clean torch

- Air bag discharge

- Acetylene contained in a bag or balloon. (cant say how it works, or how to do it)

- Use silicone to adhere tires to the ground.

- Baby oil in washer solvent tank.

- Detaching an automatic transmission’s linkage.

- Open cans of tuna under a cars seat.

- Disconnect inner door handle linkage on vehicle.

- Remove schrader valves from tires or fuel system.

- Baby powder in air vents.

It should be assumed that retaliation would be acceptable if you perform any of these against your peers. Be warned that payback is a Bi#ch.

Do you have any practical jokes, if so please comment.

The Power Of Insight and Inspection During Diagnosis

It happens often and when you least expect it. You are driving down the road (minding your own business) and your engine begins to shudder for what seems like no reason at all, and then corrects its self. The symptom will be fleeting and pass quickly, but will inevitably return. The PCM (powertrain control module) is not likely to have generated a DTC (diagnostic trouble code) to help point a you in the direction of the failed component, so you start with the fuel filter. Right? Well chasing wiring concerns is no easy task. The symptoms may mimic that of a bad injector, poor fuel volume or quality, or even the turbo charger its self. With a little luck the problem will persist long enough to catch it in the act.

In this case specifically the technician used an advanced scan tool to perform an injector “Buzz Test”. Cylinder #3 did not buzz like all of his brothers, which prompted the inspection of the injector wiring harness to cylinder #3. Not long after pulling back the corrugated protective sheathing a single circuit was found rubbing on the valve cover causing a short to ground. In effect electrifying the block and not the injector. This circuit is responsible for sending a 48v charge to the injector from the FICM (fuel injector control module) and used to actuate the high voltage solenoid releasing a pocket of high pressure fuel into he combustion chamber. The technician repaired the circuit and protected it from further damage by insulating it with more tubing and electrical tape. Took the vehicle on a test drive, and sent this one on its way with little expense to the customer.

With out this insight an individual may have replaced an injector confidently being a know problematic component. It is of the utmost importance to eliminate a circuit failure before any hardware is replaced. A small investment in time will save untold amounts of money in parts or repair. Parts stores don’t like to return “test” parts.